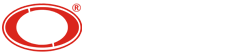

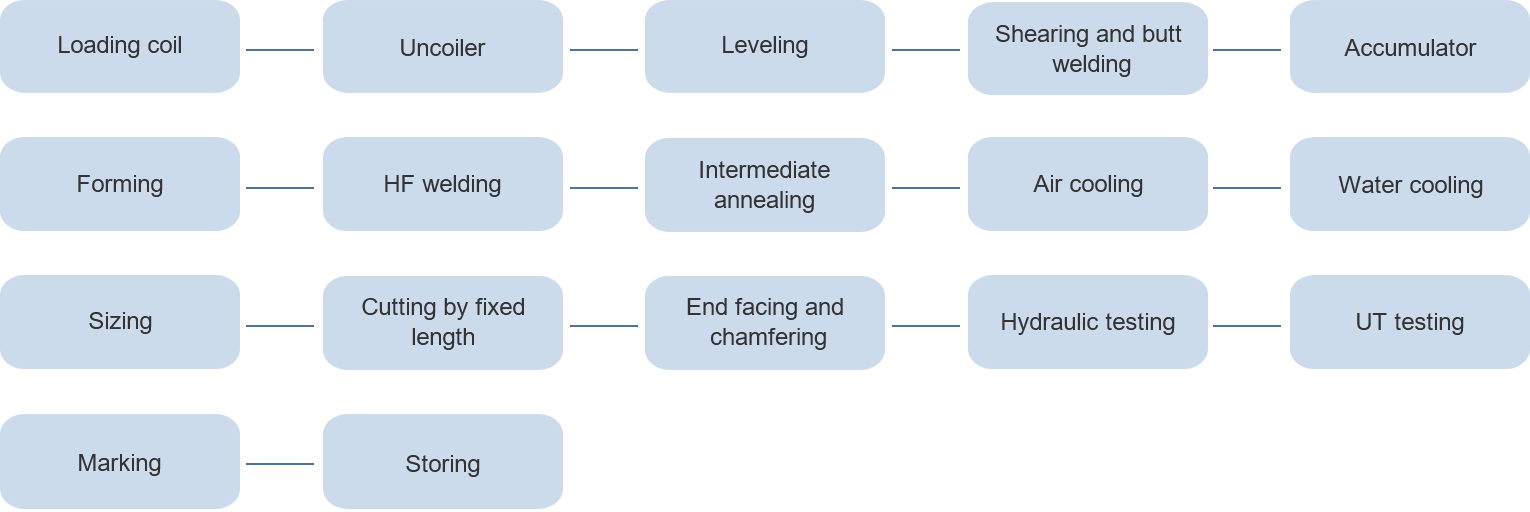

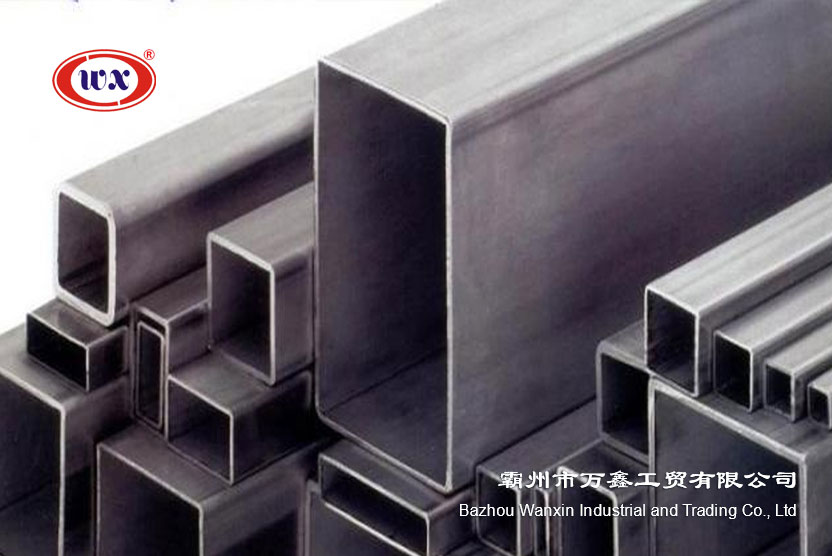

Uncoil the coil in the strip preparation section, and butt weld the end of the coil. The looper is then fed and the strip is pulled out of the looper at a constant speed through the unit. The strip is formed into an open tube in the forming unit. Then it is welded into a straight seam welded pipe with solid high frequency to eliminate the outer burrs and water cooling, and the round pipe and square rectangular pipe are calibrated and shaped in the sizing machine. The calibrated steel pipe is straightened in the Turkish head and then cut to the required length with a flying saw. After the steel pipe is sawn to a fixed length, it is quickly transported from the flying saw by the output roller and pushed onto the bench for testing. This production line meets the production process requirements of square pipe, rectangular pipe and round pipe.

ERW89 pipe welding unit is the production of straight seam welded pipe equipment in metallurgy, construction, transportation, machinery, vehicles and other industries, with cold rolled, hot rolled strip steel as raw materials through cold bending forming and high-frequency welding methods to produce the required specifications of round pipe and square rectangular pipe. The "W" forming process used in the forming process. The deformation process of this forming method makes the force more reasonable, and the material deformation of each frame of the unit is more perfect. The outstanding features of the whole set of units are: fast, time-saving and labor-saving. Unit features: high strength, strong rigidity.

Free design drawings, can undertake turnkey projects

24-hour hotline

24-hour hotline

Home

Home Tel

Tel Product

Product